Waterjet z serii POWERJET

Dowiedz się dlaczego to najchętniej kupowana wycinarka wodna w Polsce?

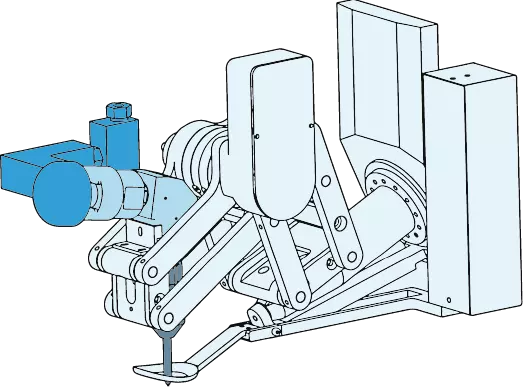

Głowica waterjet TILTER

Cięcie wodą 3D w materiałach płaskich, bryłach i niwelacja stożka “za jednym wdrożeniem”

Superokazja: POWERJET 2060

Używany waterjet z dużym stołem roboczym

(2m x 6m) i pompą 50HP dostępny od ręki

Lasery fiber i prasy hybrydowe

Sprawdź nowości w ofercie TECHJET

Co sprawia, że nasze waterjety są tak popularne?

Funkcjonujemy na polskim rynku nieprzerwanie od 2008 roku. Jesteśmy stabilnym partnerem dla wielu zadowolonych klientów. Zainstalowaliśmy ponad 100 maszyn do cięcia wodą. Nasz sukces opiera się na dwóch filarach – sprawdzonej i niezawodnej wycinarce wodnej waterjet oraz naszym zgranym zespole specjalistów, wspierającym Klientów swoim doświadczeniem.

Wydajne i niezawodne waterjety

- Ponad 100 zadowolonych klientów

- Najlepsze oprogramowanie do cięcia wodą

- Stoły robocze w różnych rozmiarach

- Wycinarki wodne w wielu konfiguracjach

- Nowoczesne rozwiązania technologiczne

Profesjonalne wsparcie techniczne

- Szkolenia operatorów maszyn

- Szybka reakcja serwisu

- Zdalne wsparcie i doradztwo

- Magazyn części zamiennych

- Serwis gwarancyjny i pogwarancyjny

Jak nasze rozwiązania przełożą się na korzyści dla Twojego biznesu?

Korpus waterjeta wykonany jest z odlewu żeliwnego, co w połączeniu ze śrubami kulowymi daje gwarancję wyjątkowej precyzji cięcia przez wiele lat. Utrzymuje geometrię w długiej perspektywie czasu oraz tłumi skutecznie wibracje, co jest nieosiągalne w przypadku konstrukcji spawanych.

Korzyść: zyskasz przewagę nad konkurencją dzięki precyzji w długiej perspektywie czasu

Odzielony stół roboczy od korpusu zapewnia bezpieczeństwo i komfort pracy. Uszkodzenie stołu lub przesunięcie go przez wózek widłowy podczas załadunku materiału nie uszkodzi mechatroniki waterjeta.

Korzyść: możesz realizować intratne zlecenia cięcia grubych materiałów, których obawiają się konkurenci

Komputer sterujący maszyną jest jednostką przemysłową opartą o bezpieczny i niezawodny system typu Unix. Został specjalnie tak zaprojektowany, aby sprostać ciężkim warunkom pracy panującym podczas obróbki wodno-ściernej. Jest odporny na pył, wilgoć, skoki napięcia czy drgania.

Korzyść: masz gwarancję większej niezawodności i nieprzerwanej pracy

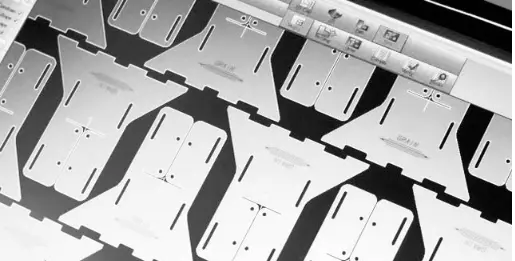

Przygotowanie procesu cięcia jest wyjątkowo łatwe i szybkie. Wystarczy wczytać rysunek, wybrać parametry materiału, jakość krawędzi i program do cięcia gotowy. Nawet bez wcześniejszego doświadczenia, po krótkim szkoleniu, praktycznie każdy może wycinać dowolne detale za pomocą waterjeta TECHJET.

Korzyść: zyskujesz komfort pracy i szybciej realizujesz projekty

Dostarczana jest w standardzie z programem do zarządzania cięciem na naszych waterjetach. Optymalizuje rozkład elementów, maksymalnie wykorzystując cięty materiał. Pozwala to generować mniej odpadów i wykorzystać cały dostępny materiał do cięcia.

Korzyść: oszczędzasz dużo materiału i generujesz większe zyski

Oszczędne, wydajne, niezawodne i łatwe w serwisowaniu pompy o mocy od 40 do 100 koni mechanicznych i maksymalnym ciśnieniu od 3800 do 6200 barów umożliwiają ekonomiczne obrabianie dowolnych detali do 30 cm grubości. Pompy przystosowane są do pracy 24h na dobę.

Korzyść: możesz w każdej chwili zwiększyć swoje zdolności produkcyjne i zarabiać więcej

Jedną z dodatkowych funkcji naszego łatwego w obsłudze oprogramowania do cięcia wodą jest moduł szybkich wycen, pozwalający na szybkie wyliczenie kosztów cięcia. W ciągu kilku minut będziesz mógł przedstawić wycenę usługi cięcia lub ocenić koszty planowanej produkcji.

Korzyść: szybciej wyceniasz usługi niż konkurencja lub oszczędzasz czas w planowaniu produkcji

W standardowym wyposażeniu maszyn do cięcia wodą TECHJET znajduje się opcja pochylania głowicy. Dzięki temu można bez problemów wykonywać tzw. ukosowanie czy fazowanie, czyli cięcie pod kątem, powszechnie stosowane w obróbce kafli lub blach do spawania.

Korzyść: możesz fazować krawędzie bez dopłacania za zaawansowaną funkcję cięcia 3D

Wysokiej precyzji śruby kulowe, prowadnice liniowe, serwonapędy, panel sterowania, a także elementy elektryczne pochodzą od topowych producentów. To gwarancja wysokiej precyzji wycinanych elementów i niezawodności waterjetów przez wiele lat.

Korzyść: Twój biznes opiera się na sprawdzonych, niezawodnych i łatwo dostępnych komponentach

Co powinienem wiedzieć o Twoich potrzebach?

Zadzwoń i powiedz mi co powinno znaleźć się w Twojej ofercie. Zadaj mi wszystkie istotne pytania na które potrzebujesz odpowiedzi.

Marcin Cegielski, dyrektor generalny

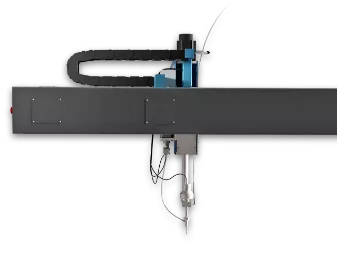

Dlaczego

jednoramienny waterjet

jest tak popularny?

Waterjety TECHJET mogą mieć konstrukcję tradycyjną, czyli bramową lub być wyposażone w jedno ramię z przeciwwagą. Oba rozwiązania są bardzo stabilne i gwarantują precyzję. Jednak konstrukcja jednoramienna ma więcej zwolenników wśród naszych klientów, bo umożliwia dostęp do stołu z trzech stron.

Wygodny załadunek materiałów i zdejmowanie wyciętych detali

Łatwe czyszczenie

i serwisowanie, a więc

i krótsze przerwy w pracy

Lepsza ustawność, co ma szczególne znaczenie w małych halach

Najwyższa jakość cięcia przez długie lata użytkowania wycinarki

Czy wiesz już jakiego waterjeta potrzebujesz?

Nasi Klienci najczęściej wybierają wycinarki jednoramienne. Oferujemy także waterjety

bramowe oraz kastomizowane. Sprawdź nasze aktualne promocje i okazje, w tym maszyny

po-ekspozycyjne i używane. W razie pytań, z przyjemnością udzielimy odpowiedzi.

Chcesz przygotować się do rozmowy z handlowcem?

Dziękujemy

za pobranie poradnika

Od czego zacząć? O co pytać?

+48 66 88 77 027

+48 66 88 77 027